Overview

Our unique Machine Care Plus® Equipment Fluid Analysis and Condition Monitoring Service

is very different from conventional methods as it delivers to the user precise

Engineering Decisions that minimise equipment support costs and maximises

availability. The service is specifically designed to incorporate:

- Multiple Equipment Types e.g. Diesel Engines, Gearboxes, Hydraulic Systems etc.

- Multiple Condition Monitoring Techniques e.g. Fluids (oil, fuel, coolant), HUMS,

Vibration etc.

- Supporting Information e.g. Asset Management, Usage, Maintenance History etc.

We have a proven track record of achievements with a number of high profile customers.

This includes more than two decades of experience working with the UK Ministry of

Defence (all three services), other Armed Forces and major Equipment Manufacturers

and we are the recognised provider of fluid sampling and analysis products and services

to the British Army.

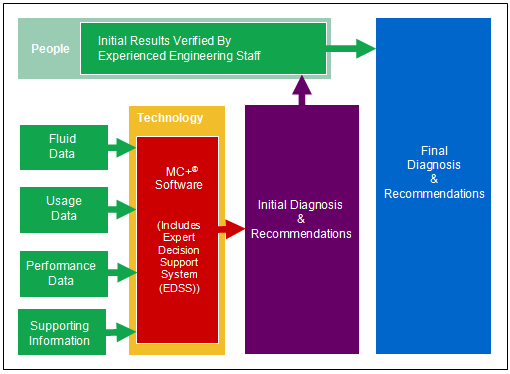

Information regarding those key processes that are central to the delivery of the

Machine Care Plus® service is available below. To view process information, click

on the relevant box in the process flow diagram opposite.

Please Contact Us with any enquiries

or if you require further information. We would very much welcome an opportunity

to discuss your equipment condition monitoring requirements.

The essence of this key process is to ensure that:

- A representative fluid sample (oil, fuel, coolant) is taken in a safe and effective

manner.

- Vital supporting information, such as identification of the sampled asset, accurate

asset usage, and any maintenance or servicing carried out on the equipment since

the last sample, is captured.

This in turn raises the quality of data and information generated by the interpretation

process.

AES Ltd will liaise with potential customers and, after an initial consultation

and assessment of customer requirements, we will advise on safe and appropriate

methods for the sampling of equipment. AES Ltd can supply a range of specially designed sampling

equipment, including sample bottle kits. Examples of the type of sampling equipment

that we can supply are shown here.

Sampling Taps

A sampling tap can be used for equipment with a pressurised oil system and a fixed

oil sampling point. AES can supply the tap with adapter styles and thread sizes

to fit most equipment sampling points.

Oil Extraction Tap Assembly

Hydraulic Tap Case Hose

Vacuum Pump

The vacuum pump is used for extracting oil samples from any equipment without a

fixed oil sampling point, or from equipment with a non-pressurised oil system. The

pump is used in conjunction with tubing and a sample bottle to enable a representative

sample to be extracted via a suitable access point such as the equipment dipstick.

The vacuum pump can also be used for coolant and fuel sampling.

Vacuum Pump

Bottle Kits

AES can supply a range of bottle kits containing sample bottles in various sizes

and quantities. Bottle kits contain everything that the customer will require for

dispatching samples for analysis, including envelopes for posting sample bottles

to the laboratory. The kits can also include Sample Information Reports (SIRs) and

SIR envelopes, should SIRs be required.

Bottle Kit

Hydraulic Bottle Kit

Sample Information Report (SIR)

The Sample Information Report is a basic form that when completed captures all of

the key information relating to the sampled asset that is used during the interpretation

process. SIRs can be supplied with bottle kits, if required, but the form can also

be downloaded from the Machine Care Plus® website, and customers that have been

supplied with a login to the Machine Care Plus® application have the ability to

complete an online version of the SIR (e-SIR). Completed SIR forms are dispatched

directly to the AES Early Failure Detection Centre (EFDC) for loading into the Machine

Care Plus® online application, ahead of the interpretation process.

Once a fluid sample has been extracted, it is sent to the laboratory for analysis.

The range of tests carried out by the laboratory will be dependant upon the type

of fluid, the type of equipment that the sample was extracted from, and the specific

test package required by the customer. Click here for more information on the various

fluid sample testing and analysis packages available. The test results data is e-mailed

to AES Ltds’ Early Failure Detection Centre (EFDC) where it is matched with its

corresponding Sample Information Report (SIR).

EFDC staff check and validate the fluid test data received from laboratory and the

information recorded on the SIR. After validation, the data from the laboratory

and the corresponding SIR is entered into AES Machine Care Plus® software application.

The data is interpreted by the Expert Decision Support System (EDSS) software and

the output is then checked and verified by highly experienced EFDC technical staff

before being fed back to the customer in the form of a detailed assessment of equipment

and fluid condition, together with corresponding maintenance recommendations. The

EDSS is designed to integrate data collected from many sources, automatically interpret

this data to provide an accurate diagnosis and make firm recommendations/remedial

actions to improve machinery health and prevent failures. It is able to handle multiple

equipment types and systems, including diesel engines, power transmissions and hydraulic,

fuel and coolant systems. Data is primarily obtained from fluid samples, but can

also be from sensors (i.e. HUMS), usage meters, physical inspection, and maintenance

histories etc. There is an important distinction to be made between testing and

interpretation. Testing produces data, whilst interpretation yields recommendations.

The EFDC is the focal point for the Machine Care Plus® Equipment Fluid Analysis

and Condition Monitoring Service. As well as validating fluid test results and equipment

data, the EFDC's highly experienced ex-military staff also monitor equipment condition,

identify any signs of distress, and alert customers whenever action needs to be

taken. Once the diagnosis, health priority and maintenance recommendations have

been committed to the system, users can securely browse or download their results

from the Machine Care Plus® online application.

The testing and data flow process is displayed on the diagram shown below.

The Machine Care Plus® online application provides customers with secure Internet

access to all of their fluid sampling results. The application provides a comprehensive

yet concise view of equipment information, equipment sample history, and sample

test and analysis results, including prioritised sample health diagnosis and corresponding

maintenance recommendations. It is also possible to record and display any servicing

or maintenance tasks that may have been carried out on equipment.

The application also includes a flexible and easy-to-use reports suite that enables

customers to configure and download a range of comprehensive reports relating to

sample analysis results and asset health. Click here to see an example report.